By Ralph M. Lermayer

Savage is once again on the leading edge of rifle design with a revolutionary new bedding system.

You don’t have to go too far back in memory to recall when Savage rifles were considered low-end or entry-level. They always shot far better than their price tags or appearance would suggest, a function of a great barrel-to-receiver lockup and some of the finest barrels in the industry. The Model 110 was originally named because that’s what it was supposed to sell for — $110.

These guns weren’t pretty, however. They were also saddled with one of the roughest triggers on any rifle, a heavy, clunky affair that couldn’t be improved by even the most talented gunsmith. That all changed when Rob Coburn, a former employee, bought the Connecticut firm and started making big changes.

Ron knew there was a great rifle inside that homely 110, so he began by dealing with the biggest problem first: the trigger. He tasked his design guys to come up with a crisp, creep-free trigger that was totally safe, but could be easily adjusted down to benchrest levels by the purchaser.

The result, the Savage AccuTrigger, sent competitors back to the drawing board because, with that one improvement, Savage had the best user-adjustable trigger found on any commercial rifle. The 110s were always accurate. Now they were incredibly accurate, and they began to seize a larger chunk of the market share. Hardcore shooters know a good thing when they shoot it.

The result, the Savage AccuTrigger, sent competitors back to the drawing board because, with that one improvement, Savage had the best user-adjustable trigger found on any commercial rifle. The 110s were always accurate. Now they were incredibly accurate, and they began to seize a larger chunk of the market share. Hardcore shooters know a good thing when they shoot it.

Following the success of the AccuTrigger, Savage began upgrading all of its rifles. Actions were modified to include right-bolt, left-ejection-port models for benchresters and prairie dog shooters. The design allows shooters to work the bolt with their right hand while their left is removing and inserting shells.

Varmint and sporter actions also were added, and the Model 10 (110) morphed into a Model 12 series including a long-range varminter and a host of target options like a totally camouflaged predator model.

Barreled actions were dropped into good-looking stocks in walnut, laminate and composite, and the 110 went from ugly duckling to queen of the ball in a few short years, with booming sales as a result.

Only a couple of things were left to deal with: the bulbous, knurled barrel nut that enhanced accuracy but didn’t do much for appearance; and a stock design for the composites that would not shift under any conditions.

Well, brace up. The AccuStock is now here, and it might change all of our thinking on how composite stocks are made.

The Options

The Options

There are two ways to make a polymer stock: simply pour liquid polymer in a mold and let it cure, or lay up layers of wet polymer and fiberglass cloth around a mold and let it cure. Of the two, the current laid-up method produces by far the stronger option. It costs 10 times more, but until now, you couldn’t get the strength from a poured (injection molded) stock. End cost is a big factor, especially in today’s economy, so Savage started with the injection molding and figured out a way to deliver the strength and rigidity of a laid-up version.

They began by adding an aluminum rail to the stock, running the full length from the action area to the fore-end. Placing a 14?-inch by 1?-inch rail in the mold, and then pouring around it took a lot of trial-and-error, but they found a way. That gave them a totally rigid product with a stable place (the metal) to add the front swivel.

The next design in that aluminum action rail is a real departure from convention. Milled onto the rail are lips that surround, grab and squeeze the entire action. As the action screws are pulled tight, the lips squeeze a bit (.0010 inch) and create tension around the entire action area. The result: metal-on-metal contact over a large surface area on the sides and full metal-to-metal contact on the bottom. By cradling the action inside the base, instead of simply on the bottom or on limited contact “pillars” or a V-block, the lockup is virtually unmovable.

According to Savage: “When the action is pulled down via the two action screws, the sides of the rail deflect to accommodate the receiver diameter and create tension on the screws. That way, the screws will not come loose in field use and recoil. The action bottoms out on the rail base while the sides maintain tension against the receiver. So just like you would lie on a bed and a bird sits in its nest, the Savage action no longer rests on steel pillars but nests itself within the new aluminum rail as the screws are tightened.

“The next design criterion was to cram the recoil lug back against the rail so that the action could not advance forward or aft, as is typically the case in recoil. A steel wedge that is pulled down by a screw holds the recoil lug firmly in place. As the screw is tightened, the wedge crams the lug and holds it tight against the rail. Once the action is nested, the recoil wedge screw is tightened to complete the assembly.”

This technology will open up a whole new approach to rifle stock bedding and lockup. From this point forward, we will have almost total control of what happens when that trigger is pulled, in the areas of both accuracy and controlling the effects of heavy recoil. Savage has once again raised the bar.

This technology will open up a whole new approach to rifle stock bedding and lockup. From this point forward, we will have almost total control of what happens when that trigger is pulled, in the areas of both accuracy and controlling the effects of heavy recoil. Savage has once again raised the bar.

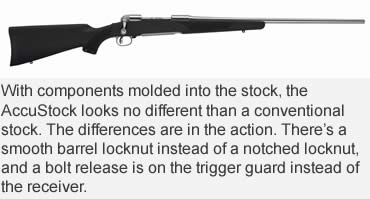

Since every component is molded internally into the stock, you won’t be able to tell the AccuStock from a conventional stock unless you look for the Savage change in design. Part of the inherent accuracy in the Savage line comes from the method used to lock the receiver to the barrel. A knurled ring nut on the rear of the barrel mates barrel to receiver and is tightened to adjust headspace.

This is the best way to adjust and control headspace, and is no doubt the most cost effective way to mass produce rifles, but the sight of that large ring breaks up the lines of a rifle and bothers the purist. That knurled ring/bolt has now been machined round and smooth, and the cuts or serrations formerly used for a spanner wrench purchase are now gone. Two small holes designed to be hidden under the barrel and concealed by the stock now serve that adjustment. On the surface, a smooth transition from the barrel to the receiver is all you see. All the new rifles fitted with AccuStock technology will be fitted with the new, smooth ring. That will be the only apparent giveaway.

The AccuStock is now available. Initial finish options are black or a special digital camo pattern. Caliber choices include the full range of Savage chamberings, from .223 to .338 Winchester Magnum, including all the shorts. With very few exceptions, the entire Model 110 and 112 lines will be fitted with the new stock, including long and short actions with either the hinged floorplate or detachable box magazine. Now, both the Ascot and AccuTrigger will be “standard issue” on almost all Savage rifles.

This is a bold move on the part of Savage, but then again, so was the AccuTrigger. And like that innovation, this one will surely shake things up.

This article was published in the August 2009 edition of Buckmasters GunHunter Magazine. Subscribe today to have GunHunter delivered to your home.